Hey guys,

In this article we see about scrubber system. Here will find answers of some questions like what is definition of scrubber system ? Types of scrubber system ? Advantages and disadvantages of scrubber system? And Why it is necessary/ mandatory in plant ?

Lets Start !

Definition : scrubber systems are group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. Basically in scrubber system, exhaust gas is passes in column from down side and scrubbing solution/material is sprayed at top. here Liquid-Gas (wet scrubber) or Gas – solid powder (dry scrubber) operation takes place.

Types of Scrubber :

There are mainly two type of scrubber :

1) wet scrubber system

2) dry scrubber system

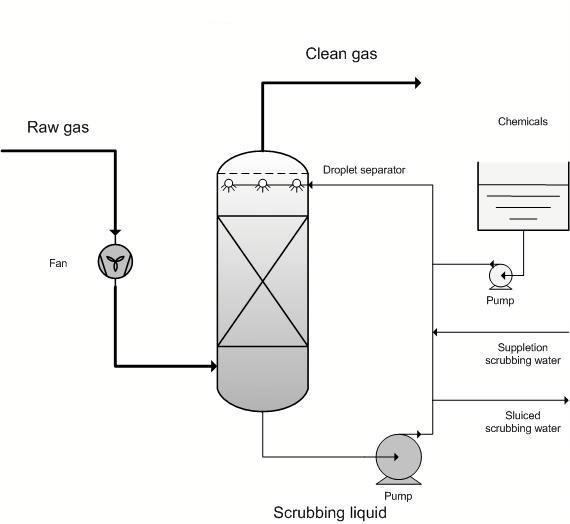

1) Wet scrubber system : In a scrubber system the gas is passes through an area where wet scrubber solution is actively sprayed. Water is used when the gas needs dust and particulate matter removed. Since this process added so much vapour to the exhaust, if the gas is vented it typically looks like billowing white smoke. The sprayed liquid collects in the bottom of the area. The liquid funnelled away from the spraying chamber and collected for disposed.

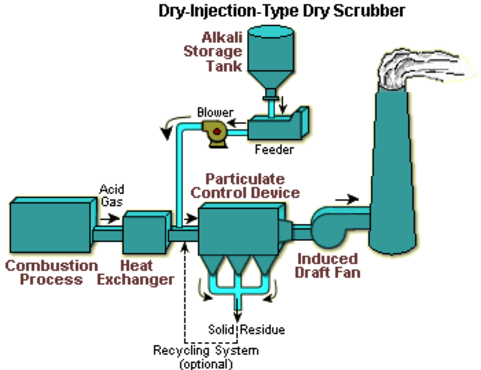

2) Dry scrubber : In dry scrubber system spray a collection of dry reagents (materials) into the exhaust. These reagents can have number of different effects depending on material they target. Some will simply neutralize a harmful material through a chemical reaction. Others causes into a different substance that is large enough to fall out of the gas stream or be caught in particle screen. Vapour in these gasses is very low, they are typically dark or invisible when vented. The system produces very little waste material, at least when compared to wet scrubber. Most of the material sprayed into the exhaust is allowed to leave, burn off in the heart of the stream or be caught in filter. As a result, the collection requirements for a dry scrubber system are much less than for wet one. This reduce the cost of the system as well as removes the cost of transporting and storing the waste water.

Advantage and disadvantage of scrubber.

Advantages

1) can handle flammable and explosive dust with little risk

2) provide gas absorption and dust collection system in single unit.

3) provide cooling of hot gases.

4) compact can often be retrofitted into existing collection system.

5) corrosive gases and dust can be neutralized.

Disadvantages

1) high potential of corrosion problems.

2) collected particulate may be contaminated

3) protection against freezing required. Certain streams may require reheating to avoid visible plume.

4) disposal of waste sludge can be very expensive

5) Requires make up water to replace purged liquid & disposed sludge.

So, why it is necessary/mandatory in plant ?

In some chemical plant, scrubber system is installed to prevent precious material loss to environment. They use selective solution to scrub specific material from the exhaust gas. And in some chemical plant, it is installed as pollution control device. Government has implanted rules to minimize pollutants from the industries. They have proposed some mandatory pollution control devices for respective chemical process plant. Without pollution control device pollution control board will not approve your process plant project.